MyBeeh started with extensive research in South Korea.

MyBeeh represents a movement to fix the issues of the current beehive. Traditional wooden beehives have been used since the beginnings of commercialised honey farming despite the issues that they have. Timber as a material is susceptible to rot, fungal diseases, and weather conditions. These intrinsic issues directly impact the bees that are contained within the walls of this outdated material. Styrofoam (EPS) hives that have been used as of late, while addressing some issues regarding humidity and rot, is still not suitable to be used for beehives. EPS material is not durable, crumbles under handling, and is not environmentally friendly (does not bio-degrade, cannot be recycled). We understand that hives should be durable for use over extended cycles, changing seasonal conditions, environmentally friendly, and adaptable for the different stages of an apiary. This driving force is what led to the creation of the MyBeeh Hive.

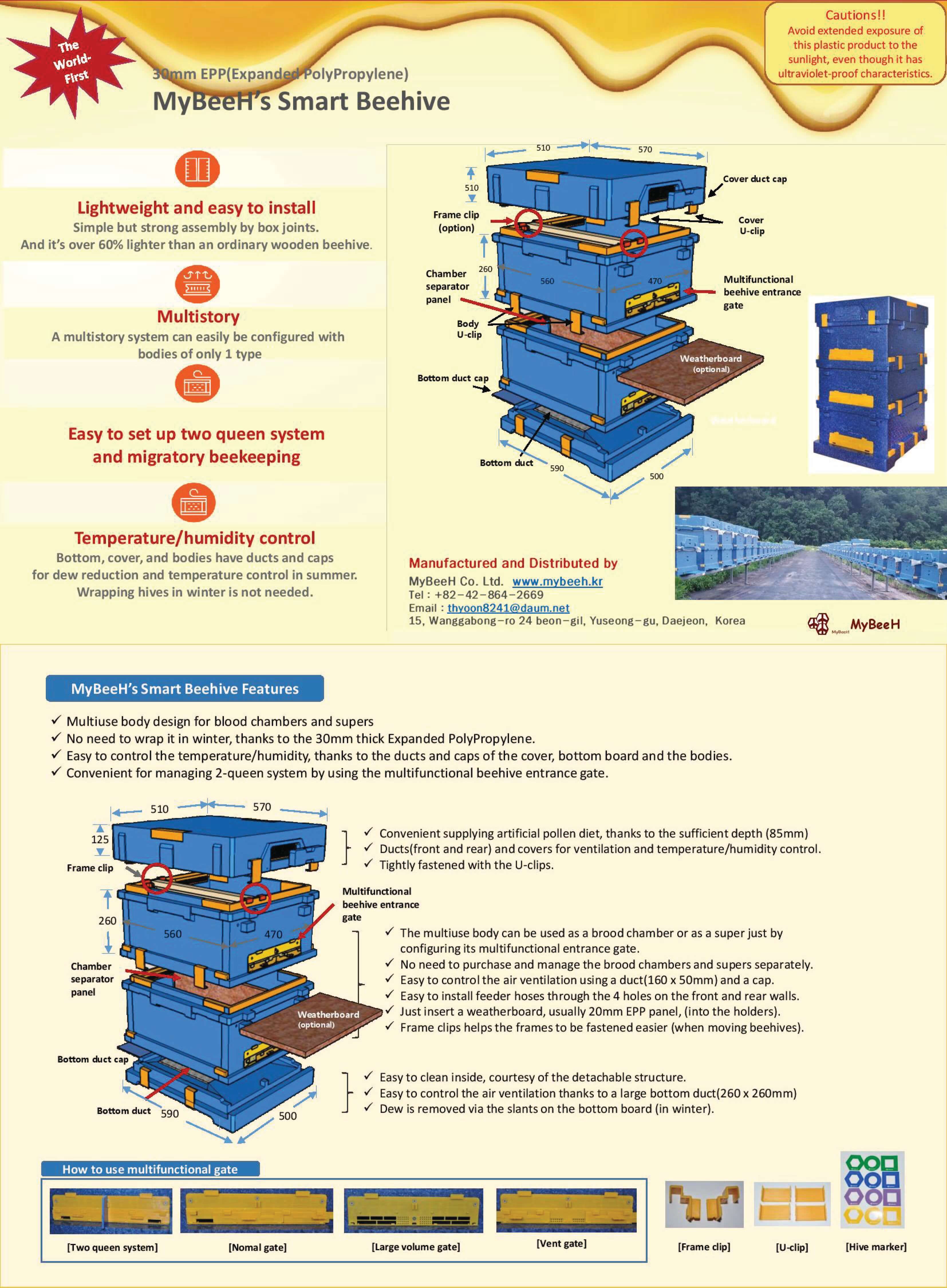

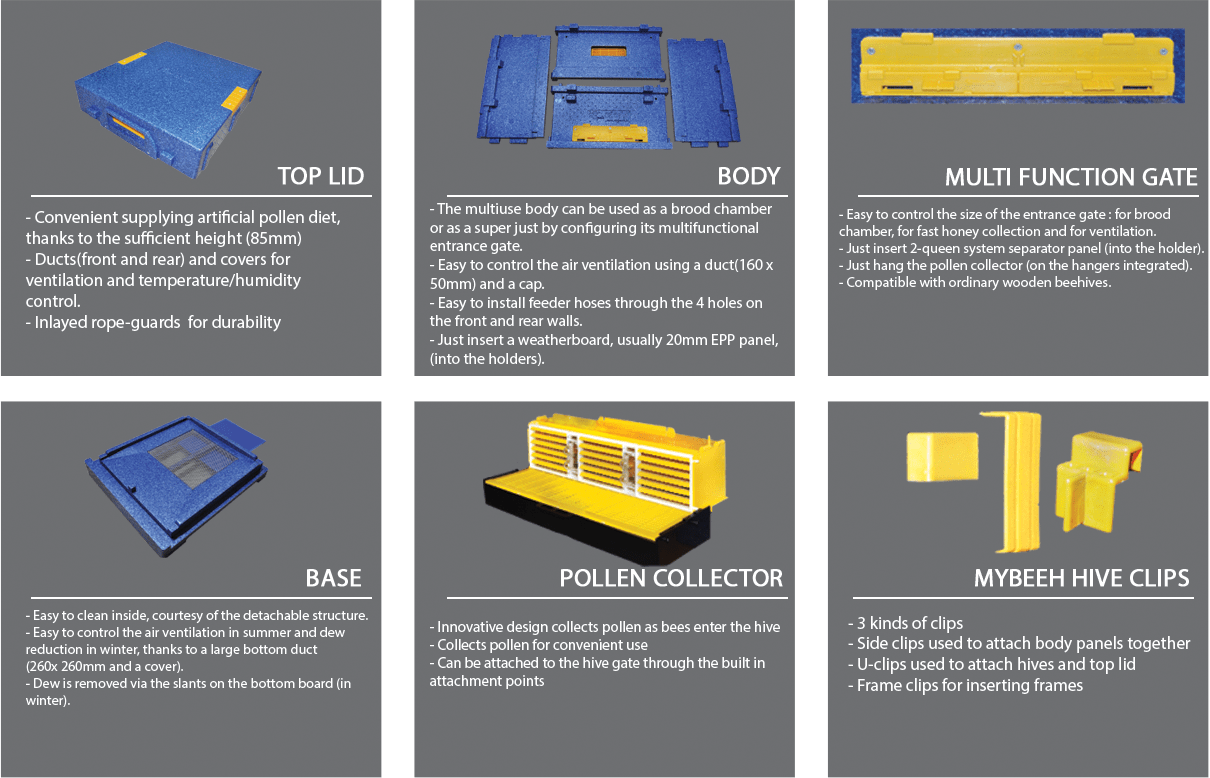

Our MyBeeh hive is primarily constructed of EPP (Expanded Poly-Propylene). Despite sharing several characteristics to EPS such as not being effected by humidity, our hives are superior in both strength and functionality. EPP is much more durable; not prone to crumbling, recovers from dents and damage, etc. These factors, as well as it’s light weight (3.1kg), high insulative properties and eco-friendliness (recyclable) made it easy for us to decide what material to make our hives from. From there on, we took extra steps to make our hives even more functional. Features such as humidity and ventilation control through vent ducts, bottom drainage, smart-gate bee entrance, pollen collector, chamber separator and more, push the MyBeeh hive beyond other beehives. See our products now.

Where did we come from?

Our EPP Bee Hive was invented by a South-Korean professor who has

closely the bee industry in order to solve some problematic challenges

that are revealed by traditional timber or plastic hives.

From our own research of the community, we found that the Australian bee

industry has also encountered this concern and profoundly, there is a

distressing amount of issues that our local beekeeping communities could

face.

What is EPP?

We worked with a material new to beekeeping supplies, Expanded

Poly-Propylene (EPP) which has traditionally often been used for car

insulation components. It has a slightly higher cost than both timber

and plastic materials comparably, but has much more attractive

characteristics for bee hives such as; lighter weight and higher

insulation than plastic (PP), and much higher strength than Styrofoam

(EPS). After several prototypes and tests in the industry, we obtained

our design certification for this new product.

How is it better and why should you bother trying it?

According to our beekeeping customers in South Korea who replaced their original timber hives to our EPP bee hives, they reported much healthier bee behaviour than traditional timber hives which led to a 30% increase in honey yield compared to their previous yields. Our EPP hives have been implemented with features such as effective ventilation, temperature consistency, and the reduction of humidity. These all contribute to the increase in yield of our hives.

1.Ease of management

LIGHT WEIGHT

3.1kg for the single hive, 1.5kg for additional layers.

STRONG & DURABLE

It's inherent properties allow substantial strength handling over 100kg of weight. And does not chip/crumble like standard styrofoam (EPS) hives

EASY TRANSPORTATION WITH CLIPS

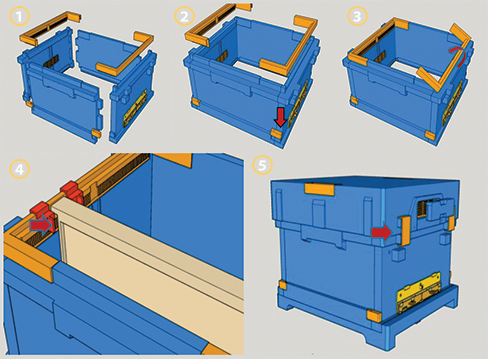

Top & Body / Body& Body/ Body & Frame No more concerns with wind, transportation and pollination with our clip system. The unique design allows the assembly and modification of the hive without extra tools.No more extra works !

QUICK & EASY INSTALLATION

No need to paint ! Just puzzle it ! Generally it takes time less than 15minutes !

EASE OF USE WITH ACCESSORIES

A number of modular accessories such as the clip system, pollen-collector, weather boards for awning, and queen divider makes management an easy task.

2. Bee-friendly design

VENTILATION

Ventilation holes assist the flow of air, keeping the hive cool. The provided covers also allow beekeepers to easily maintain their hives for all weather conditions and seasons.

TEMPERATURE REGULATION

The 30mm thick EPP walls keep the internal temperature stable and this directly impacts the bee's behaviour, inclining them to produce honey more consistently.

WATER DRAINAGE

Sloped bottom panel and drainage grills help get rid of water and reduce humidity..

ALL IN ONE, HIVE BEETLE MESH+TRAP

We know 'hive beetles' have been the most problematic and harmful insect for our bees and our beekeepers. To provide the best product, we obtained the mesh protections on the side grills and also mesh entry on the bottom panel toward oil trap. This oil trap is very easy to maintain, just simply fill the oil and push into the bottom panel of MyBeeh!

MULTI-FUNCTION ENTRANCE

Bee entrances should be able to be adjusted in size for changing conditions. The multi-function door helps provide a controlled flow of bees, also reducing pest breaches.

COLOURED HIVE

According to research performed by the University of London, It was found that bees have a higher affinity to the colours violet and blue, in their studies resulting in a 40% higher yield (Source. Sciencedaily, Bees Seem To Benefit From Having Favorite Colors, https://www.sciencedaily.com/releases/2007/06/070624141133.htm _)